INSPIRATION

It all starts with research.

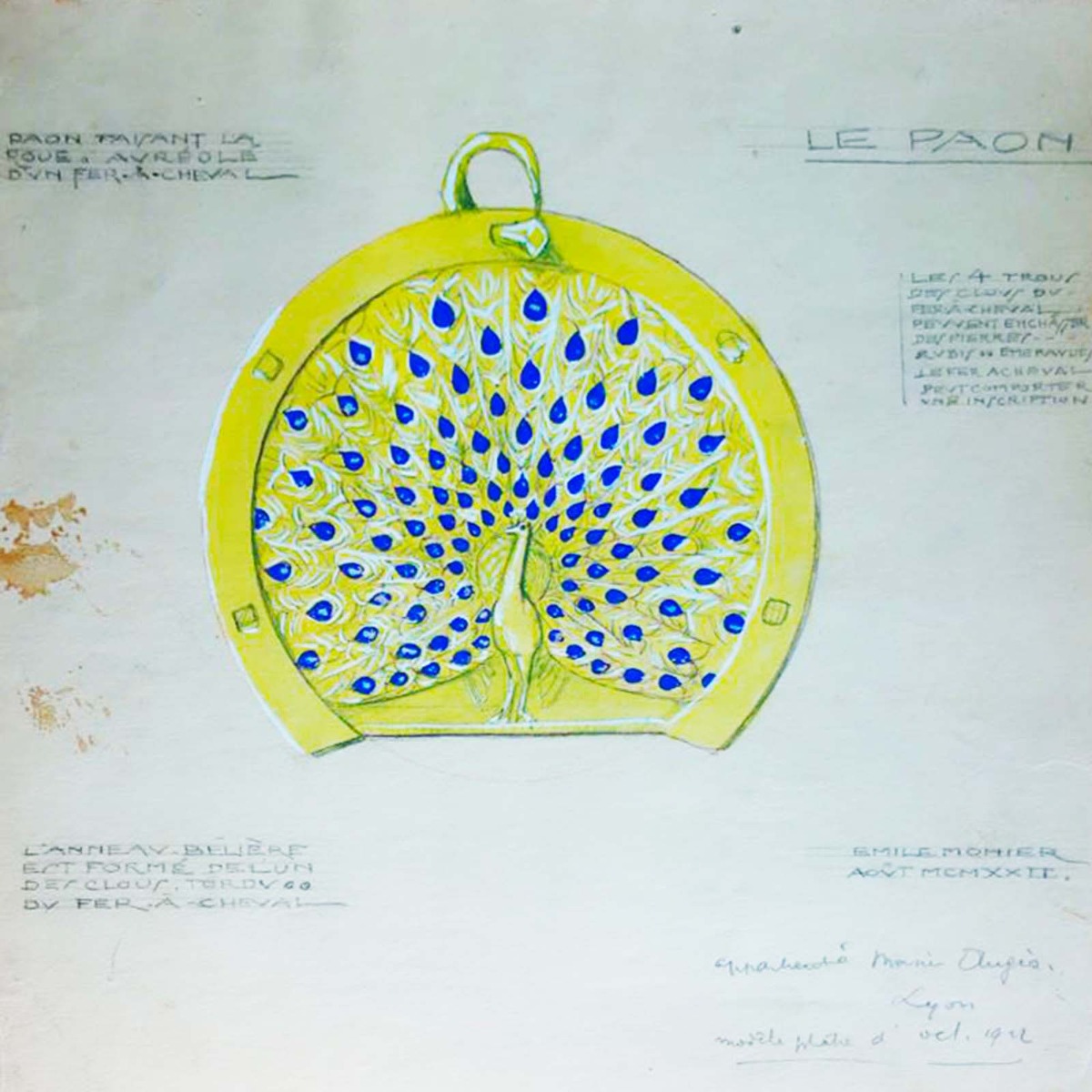

Depending on the themes imposed or the desires of the Maison, the designer is led to look for images, concepts always in accordance with the values of Augis:

the family, the message of Love...

Several visuals are brought together and serve as inspiration for the shapes, patterns, volumes.

For religious medals, there is no shortage of sources:

church statues, religious icons, paintings by masters, etc.

It is the sensitivity of the designer which is the key to a successful drawing.

The most important thing remains that the drawing can tell a story, “that everyone can make their jewel their own”, confides to us our designer Louise.